Boat Frame Replacement Information Form

We'll Contact You Back ASAP! We're Currently Receiving A High Volume Of Requests. We Appreciate Your Patience! Do Not Hesitate To Follow Up On Your Request With Us.

Easy, Quick And Effective. Get A New Windshield In Less Than 3 Weeks (Depending On Shipping Time)

Complete The Form Below.

Receive Email With Instructions.

Follow Tracing Instructions . (If Required)

Dismantle And Ship Frame.

Receive Order Confirmation.

Install Your New Windshield!

We'll Contact You Back ASAP! We're Currently Receiving A High Volume Of Requests. We Appreciate Your Patience! Do Not Hesitate To Follow Up On Your Request With Us.

Our material offers superior durability with a sleek, glass-like finish.

With a wide viewing angle, our material is the safest plastic windshield on the market.

No visual warping, no blind spots and no object shifting.

Our material is virtually indestructible.

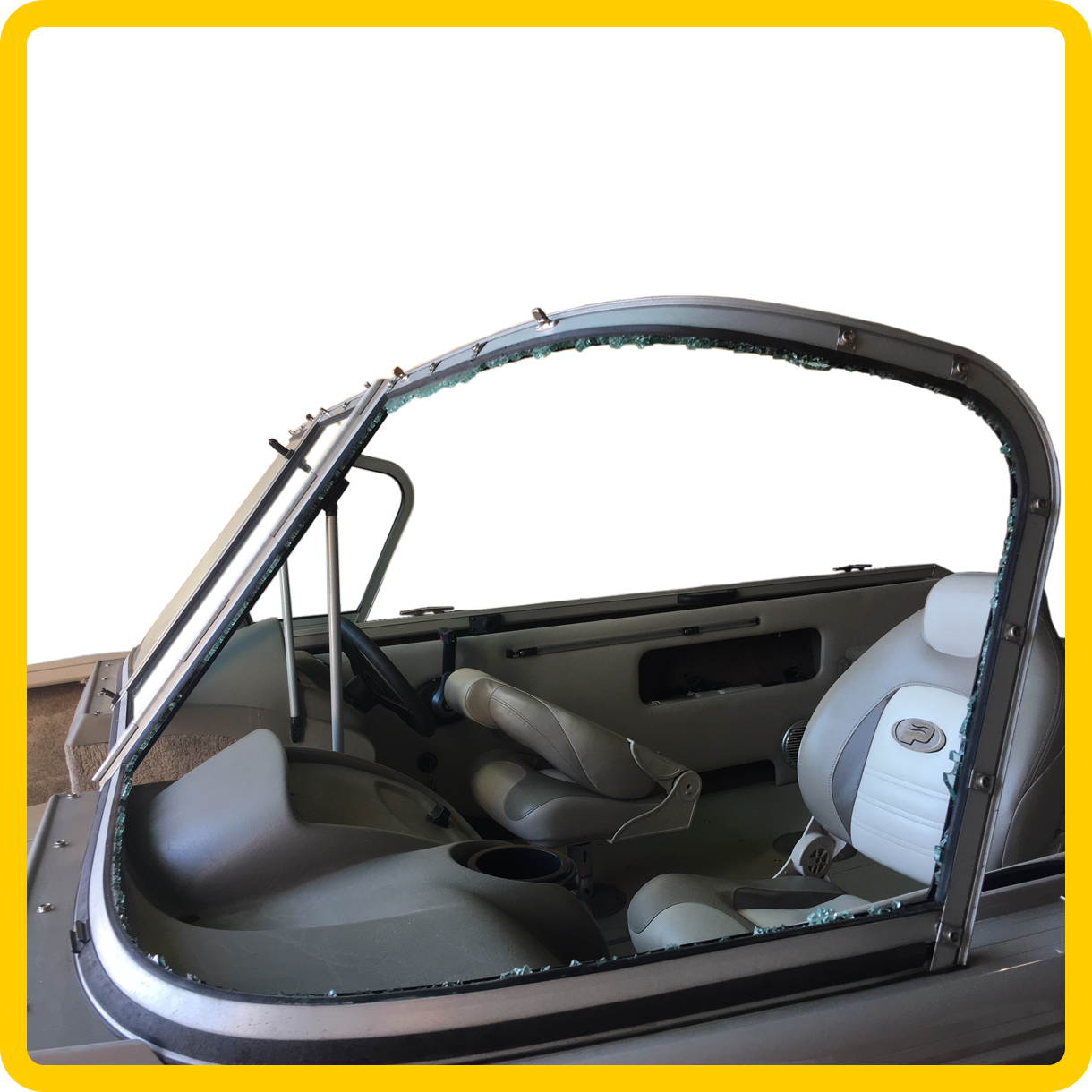

Highway towing, opening the center door too hard, snow collapsing the tarp, boat marina accident, we've heard it all.

You can rest assured with our windshield, that it will never shatter or break again.

Won't yellow out quickly like other plastic windshields.

Experience unparalleled U.V. resistance with our A.R. products that last years, not months, without yellowing or hazing.

Invest in lasting quality.

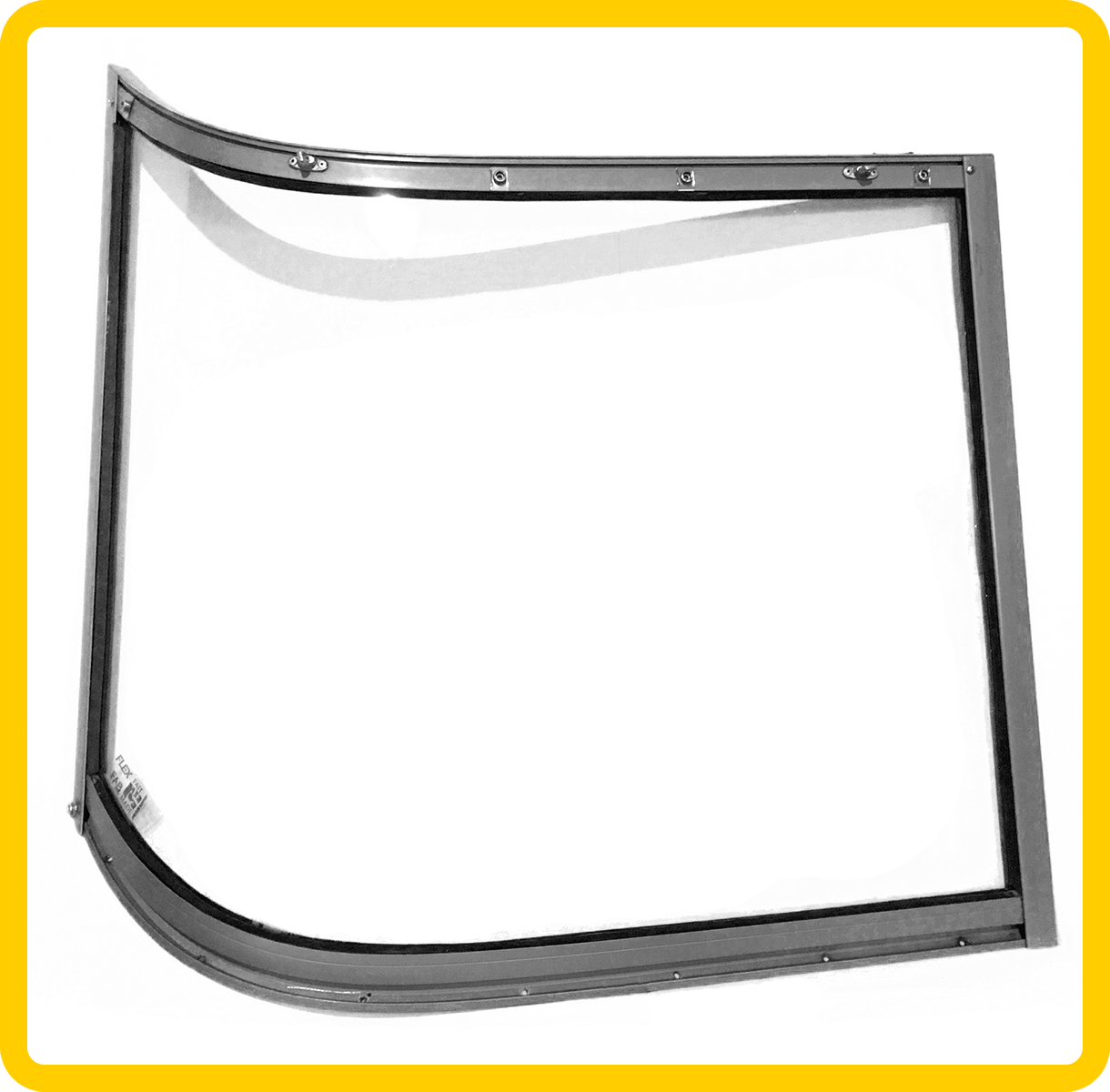

Crafted with precision and durability.

Ensuring a perfect fit for your boat frame.

Unlike Other Plastics, Our Material Is Rated For Optics.

Just Like The Original Glass, Experience Our Material's Superior Optical Quality, Providing Clear Visibility For Safe Boat Navigation.